Completely renovated interior construction facility in Echt optimises production process Linssen Yachts

- Details

The production of the high-quality interiors for Linssen motor yachts takes place in the completely renovated interior construction facility in Echt, located just five kilometres from the boatyard in Maasbracht. This location forms an essential part of Linssen Yachts' integrated Logicam production process, in which efficiency, precision and quality are central.

In recent months, the production location in Echt has been thoroughly modernised. The hall has been fitted with a new concrete floor, completely renewed cabling and air and humidity systems, and modern safety systems. At the same time, the entire workflow was redesigned according to the principles of lean manufacturing and tailored to the specific requirements of yacht building.

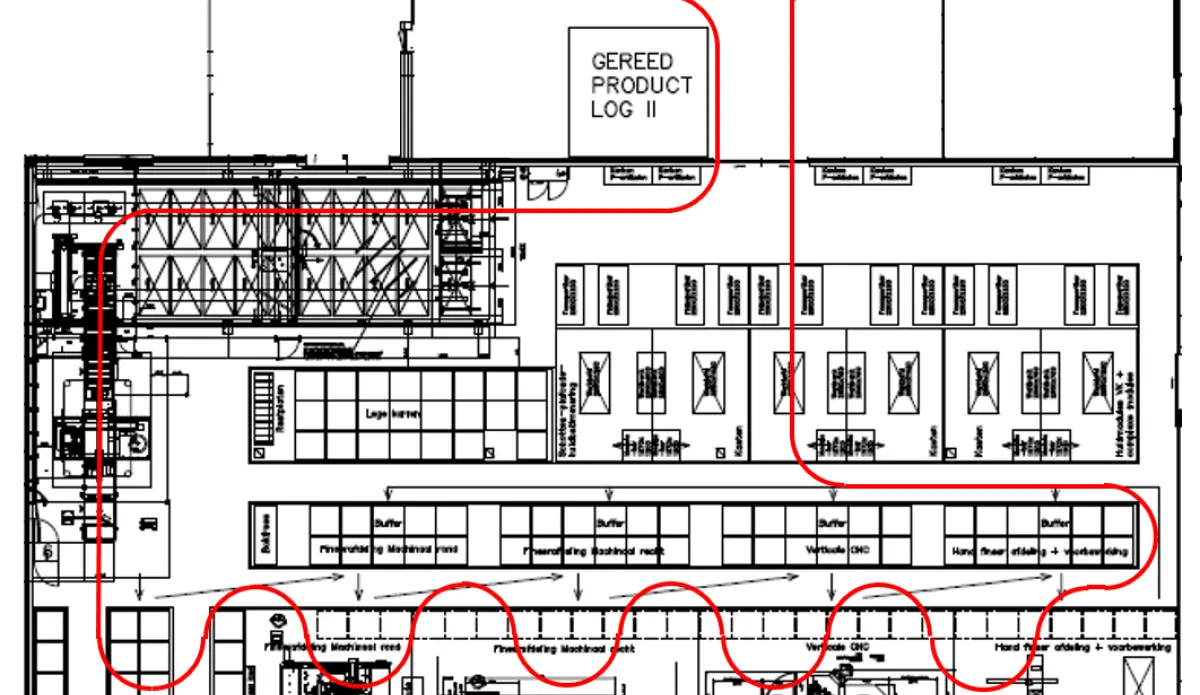

The production process starts with the delivery of plate material. These plates are then automatically stacked in a so-called 'chaotic' plate warehouse, where only the system knows exactly where each plate is located. Once a project goes into production, the correct sheets are collected into a project-specific sheet package.

An automatic sticker printer provides each panel with a unique identification sticker, after which the material is precisely positioned for further processing. An advanced three-axis nesting milling machine with 22 tools processes the panel material with extreme precision. The milled parts are discharged via a bleed conveyor for further processing.

Depending on the shape of the milled parts, they are veneered: free forms go to a band veneer machine that can finish complex contours, while straight edges are finished mechanically using a separate veneer machine. For more complex or six-sided operations, a vertical CNC router is used, followed by manual finishing operations such as sawing or additional veneering.

The various interior elements are then assembled in six specially equipped assembly islands. Each workstation is equipped with an ergonomically adjustable work table, ensuring quality as well as working comfort and safety.

After assembly, the complete interior modules are bundled at the finished product assembly area. From here, transport takes place to the yard in Maasbracht, where the interior parts are prepared on the shop floor of the three Logicam lines for installation in the yachts.

With this investment in the facility in Echt, Linssen Yachts once again confirms its leading position in the market of luxury displacement motor yachts and underlines its continuous pursuit of innovation, quality and efficiency within the entire production chain.

Logiwood interior facility